powder, and the purification treatment combining high temperature method.

| Sign In | Join Free | My entremaqueros.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My entremaqueros.com |

|

Place of Origin : Hunan, China

Brand Name : OEM

MOQ : 1

Price : $40,000

Type : Induction Furnace

Voltage : 380

Weight : 5 t

Max Temperature : 2850

Heat Method : induction heating

Working Temperature : 2400

Temperature Measurement : far infrared

Furnace Body Material : SS 304

Furnace Structure : vertical

Cooling System : closed water cooling tower

Control Method : Manual or automatic operation

Temperature Difference : ±3.5, ±5, ±8

Furnace Atmosphere : Vacuum or inert gas protection

Core Components : PLC, Pump

Loading Volume : 10-40, 40-120, 120-250

Model | GJC-DCL-4 | GJC-DCL-10 | GJC-DCL-15 | ||

Product capacity | 50-90 | 100-140 | 150-200 | ||

High temperature | 2850 | 2850 | 2850 | ||

Heat method | induction heating | ||||

Control method | Manual or automatic operation | ||||

Loading volume | 10-40 | 40-120 | 120-250 | ||

Temperature difference in constant temperature Zone(℃) | ±3.5 | ±5 | ±8 | ||

Furnace working atmosphere | Vacuum or inert gas protection (slightly positive pressure) | ||||

|

|

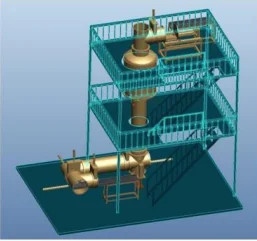

SS 304 Material Vertical Graphitization Furnace with Closed Water Cooling for Continuous Purification Images |